|

This article contains affiliate links

Most gardens and outside spaces are not naturally flat and level like inside environments. Natural undulations mean most gardens have a series of varying level changes. The chances of this are even higher the larger the garden you have. The problem is steep and undulating ground is not comfortable to move across or inhabit. Consequently it is very common to wish to level up such gradients into a series of terraces. This allows for a series of more usable flat areas which can have varying surfaces and functions. The primary installation in the formation of landscape terraces is retaining walls. These can be constructed in a variety of heights, thicknesses, shapes, forms and materials. In this article we will describe the three main types of garden retaining wall and the tools needed to build them. Main types of garden retaining wall

Brick retaining wall

Retaining walls built with bricks are both durable and aesthetically pleasing. Bricks being made from natural materials rarely colour fade over time and come in a wide variety of colours. Brick walls due to multiple units have a pleasing visual texture and even more so with some colour variation. Brick retaining walls should be at least two bricks thick for retaining structures. Weep holes should be incorporated into the structure to allow water to escape. Bricks average about £1 each and it is very typical for an average retaining wall to require hundreds. This combined with the need for skilled labour makes the brickwork option expensive. Concrete retaining wall

There two main types of retaining concrete wall; concrete block and in-situ. In-situ concrete consists of pouring wet concrete mixes into formwork moulds with reinforcing. This method has the advantage of being formed into any shape or form. However generally on a small garden scale these are a little impractical. It is much more convenient to build concrete walls using concrete blocks. These can be regular concrete clocks laid on end for thickness or hollows filled with wet concrete. All concrete retaining walls will need to be built on a robust concrete foundation. The taller the retaining wall the wider and deeper the foundation for extra strength. Concrete walls are more affordable than brickwork with the added benefit of multiple facings. Concrete walls can be smooth rendered, pebble dashed, tiled or clad in natural stone. Timber sleeper retaining wall

One of the most popular and affordable ways to build retaining walls is with treated timber sleepers. Sleepers not only look good they are quick and easy to build. These do not necessarily require a continuous, concrete foundation and instead can be fixed to anchor posts. These are normally 4x4 treated timber posts concreted 600mm into the ground. Sleepers can also be set vertically into the ground with a concrete foundation. This can be better for realising curves and to mirror undulating landform. The only downside to sleepers is they have a tendency to decay after around 20 years. Tools for excavating and ground works

A very large part of building retaining walls is the excavation and groundwork levelling. Not only must foundations be excavated soil must be backfilled and levelled out after construction. Hence below we listed the best tools for retaining wall excavations and levelling below. 1. Spade

Spades are extremely effective at digging out foundations to retaining walls. They allow you to cut out consistent slabs of soil to be carted away. Spades can also chop neat sides to excavations and spread wet concrete into foundation trenches. 2. Shovel

Shovels are a must have tool for building retaining walls. During the excavation stage they can be used to collect loose soil and load it into wheelbarrows. These are perfect for cutting flat bottoms to foundations and loading up barrows with concrete aggregates. 3. Graft

Grafts are digging tools with long shafts and small forged spades at the end. These are perfect for loosening hard ground and for chopping out roots and ground obstructions. Grafts are particularly great at digging down deeply to secure anchor posts. 4. Mattock

Mattocks are very similar in shape to pick axes but with a more robust and compact form. These tools are excellent at chipping out tough ground and chopping out roots. Mattocks are also great at dislodging buried obstacles such as concrete and other builder’s rubble. 5. Wheelbarrow

Wheelbarrows have a vital role in transporting excavated soil away to be disposed of. They can be the perfect tool for loading up skips and carting aggregates and cement to site. Wheelbarrows are the perfect vessel to wheel wet concrete mixes to foundation trenches. 6. Laser level

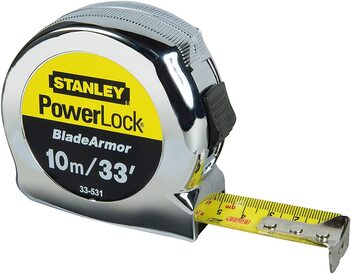

Setting out foundations and working out foundation levels are one of the most important tasks for building retaining walls. You should always aim to have the first 100mm of retaining wall under the soil surface. This is to hide the concrete foundation and allow lawns to grow up to the wall if desired. Laser levels provide a fast and effective way to plot landscape levels over distance. 7. Tape measure

Tape measures are essential for checking the depths of foundations while digging. These will enable you to make sure you reach your minimum required concrete depth and width. Tape measures will also allow you to quantify the amount of concrete you need to fill the foundations. 8. Landscaping rake

Landscaping rakes are much larger and stronger than conventional gardening rakes. These are perfect for raking excavated soils level as you dig. Very often excavated soil for foundations can be used to infill voids behind the retaining wall. Landscaping rakes are very effective at levelling out soil in low spots as you dig. Tools for brick and concrete retaining walls

The most common types of retaining walls are masonry based. These include concrete, brick, natural stone and rocks. However brick and concrete are the most typical and practical for the average garden. Below we list and describe the best tools for building concrete and brick retaining walls. 9. Cement mixer

Cement mixers are the staple method of mixing concrete and mortar mixes by hand. Very often garden projects do not warrant pumping in large quantities of pre mixed concrete. Mixers are useful for laying foundations, bricklaying and producing rendering mixes for retaining structures. 10. Bricklaying trowel

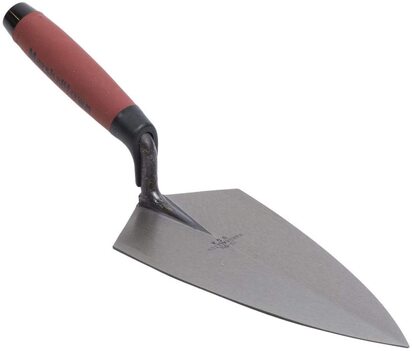

Bricklaying trowels are the best tools for laying bricks, blocks and copings to retaining walls. They are also a great multifunctional tool to have around for most landscaping projects. 11. Pointing trowel

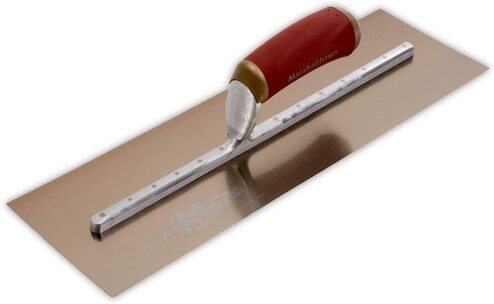

Pointing trowels are like miniature versions of bricklaying trowels with rounded ends for neat finishes. Pointing trowels are good for filling in mortar gaps and smoothing down any areas of exposed mortar. These are also very useful for scraping tools clean at the end of the day. 12. Rendering trowelIt is often that concrete retaining walls are rendered to provide a smooth and modern finish. Rendered retaining walls have the added advantage of being able to be painted any colour. Rendering trowels are the perfect tool to coat concrete walls with render. 13. Tiling trowelAnother great benefit of building concrete or brick retaining walls is you can both tile and clad them. There is an extensive range of external tiles and natural stone cladding which can literally fit to any garden style. Tiling trowels are perfect for applying even beads of adhesive to bed on any cladding material. 14. Jointing iron

If you are building your retaining wall with brickwork you will want to finish joints neatly. The best way to do this is with a jointing iron. This will provide a quick and easy way to point joints smoothly. 15. String line

String lines are essential for building straight retaining walls over distance. The more distance the wall covers the more chance a wall line can kink and bow. Hence laying bricks and blocks to a good string line is always worth it. 16. Club hammerWhen working with any type of masonry it is always handy to have a club hammer to hand. These hefty and robust hammers are great for knocking heavy blocks into position as you build. Club hammers are best used with bolsters to chip down and chop out sections of masonry. 17. Bolster

Bolsters are a type of short and broad masonry chisel. They can be used to neatly break concrete blocks and bricks as you build. 18. Spirit levelSpirit levels are essential tools for building any type of retaining wall. However they are used with a much greater frequency when laying concrete blocks and brickwork. Their long straight edge combined with the bubble guide is perfect for levelling courses and plumbing corners. 19. Rubber mallet

Rubber mallets are traditionally used to bed down stonework onto mortar mixes. Mallets also provide a good way to tamp bricks and blocks into position without chipping them. These are also effective for applying natural stone cladding and copings to retaining walls. 20. Buckets

Buckets are always useful to have to hand while building retaining walls. Their most common uses are holding water for mixing mortar, concreting and setting in anchor posts. Buckets can also be used to house smaller tools while working. Tools for building timber sleeper retaining walls

Timber sleepers are a fantastic material for building new retaining garden walls. Unlike brickwork and concrete block, sleepers do not need continuous concrete foundations. They are also extremely quick to put together making them a much more affordable option. However sleepers are much more cumbersome than traditional wood working timber. Consequently using the right tools for the right job is essential when building sleeper walls. Below we have listed the tools you will need to build retaining sleeper walls in your garden. 21. Coarse hand saw

Many are not keen of the idea of using a handsaw to cut through thick timber sleepers. However as long as you have a sharp saw and are good at accurate cuts they are manageable. Hand saws are much better for making nimble cuts to bracing timbers and posts. Sometimes these are better for cutting awkward angles and troublesome joins. coarse hand saw 22. Circular saw

Circular saws will not cut all the way through sleepers but will cut about two thirds of the way through. This is a good way to set up a perfectly square cut which can be completed with a hand saw. These power saws are quick and convenient to cut many grades of timber fast and efficiently. 23. Chainsaw

When it comes to cutting thick, timber sleeper’s chainsaws can set you up for speed. However cutting sleepers neatly with a chainsaw can be very challenging and takes some experience. I would not recommend using chainsaws for sleeper work if you are inexperienced. However there are work horses available which make sleeper cutting with a chainsaw easier. chainsaw 24. Foldable chainsaw horseFoldable chainsaw horses have a triangular structure which allows you to rest sleepers securely when cutting. The chainsaw slots into a secure mount which allows the cutting blade to be lowered squarely onto the timber. This ensures an accurate cut with as smooth a finish as possible. 25. Carpenters squareThe key to building professional retaining walls with sleepers is accurate cutting. The best way to make sleepers join neatly is to mark out perfectly square cuts. Carpenters squares allow you to do just that and are also useful for marking and cutting anchor posts. 26. Carpenters pencil

These robust pencils are perfect for any external timber construction. Their thick shaft and graphite centre make marking sleepers accurately in all weathers easy. 27. Power drillAs sleepers are thick and can be full of dense knots a good quality power drill is needed to fix sleepers together. Power drills can also be useful to bolt fixings through sleepers and into anchor posts. 28. Cordless drill

Cordless drills can be utilised to fix small timber plates onto sleepers to fix them into position. Sleepers can be joined this way into continuous sections before bolting to posts. Sometimes good quality, cordless, combi drills can be used to fixed sleepers together. One drill can bore out pilot holes while the other can be used to screw fixings using the hammer function. 29. Drill bit setIt is always useful to have a drill bit set to hand when working with sleepers. Drilling thick timbers can lead to some bits snapping making it essential to have ready replacements. 30. Extension cableWhen using multiple electric power tools for external timber work a long extension cable is vital. The best for building retaining, sleeper, walls are those with 50m cables and waterproof plug sockets. 31. AugerAugers are not obvious tools for building sleeper walls but they are perfect for boring out post holes. These powerful, ground excavating, drills can bore multiple holes to set in anchor posts flush with sleepers. These can provide the extra strength and stability to make your retaining wall last the test of time.

Thank you for reading our article on the best tools for building retaining walls. If it helped with your search why not share it? This really inspires us to write more useful content in the future! If you require retaining wall services please don’t hesitate to contact us here.

'As an Amazon associate I earn from qualifying purchases'

8 Comments

3/14/2022 02:35:53 am

I am most captivated when you mentioned that sleepers don't only improve the look but are also simple and fast to build. My mother wants to enhance our property. I think we should hire a concrete sleeper wall contractor to make it happen.

Reply

3/22/2022 04:47:23 am

It was captivating when you shared that sleepers are not just attractive, they are also fast and simple to build. That's probably why my mother is planning to have concrete sleeper retaining walls. I think it's a good idea, so I will tell her to hire a contractor for the installation.

Reply

Thanks for helping me understand that there should be two layers of bricks when building retaining structures. I will keep that in mind when I hire contractors for the brick retaining walls that I wanted for my backyard. It will match the overall design of my home while ensuring that my patio and pool would be protected if ever there are instances of soil erosion.

Reply

11/17/2022 03:58:45 am

It's interesting to know that there would be no need for a continuous, concrete foundation for timber sleeper retaining walls, because they can be installed with anchor posts. I will make sure to choose that type of material once I hire a retaining wall supplier for my property this month. We definitely need this installed in our backyard to ensure that we can protect our pool from the snow in the winter season, since we are near a slope.

Reply

1/11/2023 12:13:23 pm

Thanks so much for talking about all the tools and some materials that would be helpful when building a retaining wall. My sister wants to put in a garden and she wants to elevate a few parts so we need to put in retaining walls. we'll have to look into finding a place that sells building materials so we can get all the supplies we need for the project.

Reply

1/12/2023 12:36:47 pm

I'm glad you said that bricks have a pleasing visual. My husband wants to look into building retaining walls on our front lawn in a couple of weeks, so I wanted to learn more about the different types of materials to choose from. I really appreciate you helping me learn more about the different types of retaining walls. We'll keep these tips in mind as we search for supplies to work with.

Reply

3/29/2023 08:28:49 pm

I'm glad that you talked that the appropriate retaining wall should have a proper design for the whole surface. A couple of days ago, my father mentioned that he was planning to replace their current retaining walls because it is causing soil erosion in their garden. He asked if I had any idea what would be the best option to fix the surface level. I'm grateful for this informative article, I'll tell him that consulting a well-known retaining wall service can provide information about the process.

Reply

5/15/2023 06:05:48 am

It's great that you explained that retaining walls constructed with bricks are both stable and aesthetically pleasing. My friend wants to get their retaining wall replaced. I should advise him to hire an expert in retaining wall replacement to ensure quality work.

Reply

Leave a Reply. |

The Author

|

Landscaping services across Buckinghamshire, Amersham, Aylesbury & High Wycombe

Hyde Heath, Amersham, Buckinghamshire |

|